6 Common Faults and Spare Parts of Overhead Cranes

Overhead cranes play a key role in various industries, promoting efficient material handling and simplifying operations. However, after a long period of time and high frequency of use, affected by factors such as excessive load, bridge cranes are prone to operational failures, which in turn fail to function properly and bring certain inconveniences to industrial production. Therefore, it is necessary to study the parts failure, controller failure, brake failures, reducer failures, electrical failure and other common faults, collect the corresponding spare parts, and take targeted measures to deal with and repair to ensure that the bridge crane can run smoothly.

1. Faults of Hook

- Fatigue Cracks: Fatigue cracks may appear on the surface of the hook due to frequent overloading and excessive stress during use. Material defects and poor quality can also cause the hook to deform or break, leading to accidents.

- Opening and Hazardous Section Wear: Due to frequent use, the crane hook is prone to problems such as increased opening and wear on the hazardous section. The movement and friction of the wire rope can create grooves on the hook. When the opening of the hook exceeds 15% of its original size or the hazardous section wear reaches 10% of its original size, it weakens the strength of the hook and can cause deformation or detachment, resulting in accidents.

- Plastic Deformation: Prolonged overloading or exposure to high-temperature radiation can cause plastic deformation in the opening and bending parts of the hook, which may result in the detachment of heavy objects and accidents.

Overhead Crane Hook Troubleshooting

- In case of fatigue cracks on the hook, it should be replaced immediately.

- According to the scrapping regulations for hooks, it should be scrapped if the opening exceeds 15% of its original size or the hazardous section wear reaches 10% of its original size. If it does not exceed the standards, it can continue to be used under observation or with reduced load, but it is not permitted to use the welding rod to repair and then use again.

- In the case of plastic deformation occurring in the opening and bending parts of the hook, it should be replaced. In high-temperature or metallurgical operating environments, when the temperature of thermal radiation exceeds 300 degrees, a radiation shielding plate can be welded to isolate the heat radiation and protect the hook.

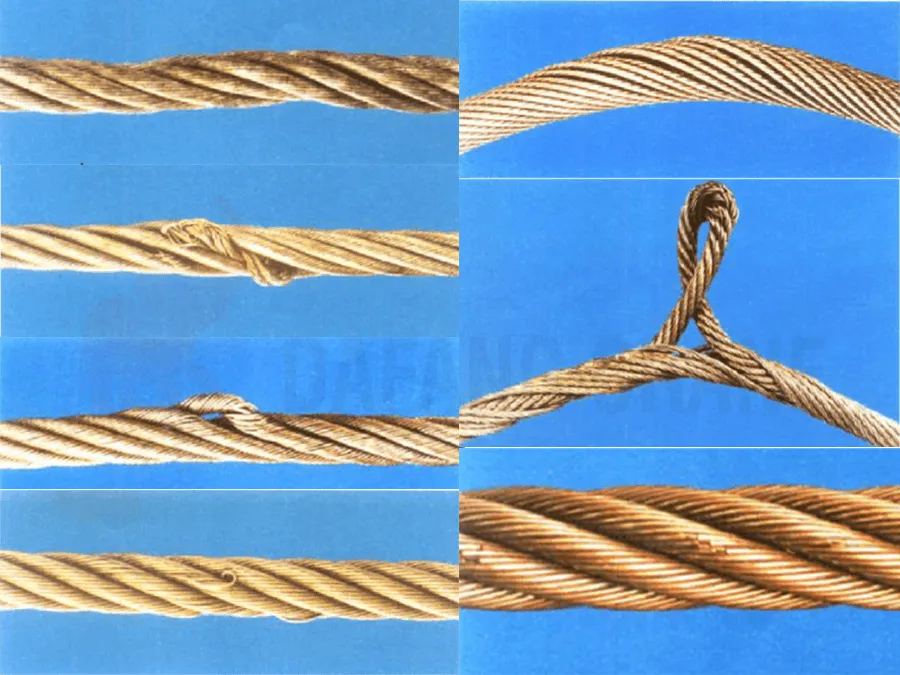

2. Wire Rope Faults

- Twisting: Under normal working conditions, the wire ropes on both sides of the movable pulley group should be parallel and non-interfering. However, when the wire rope “twists,” the ropes on both sides of the movable pulley group cross each other in a “figure eight” or “twisted” shape. This phenomenon occurs as a result of internal stress concentration caused by the installation or replacement of new wire ropes over time.

- Random Rope Twisting on the Reel: When this situation occurs, it is caused by a failure in the rope guide. The rope guide is installed on the reel and its function is to ensure the smooth unwinding and winding of the wire rope from the reel and to prevent the rope from tangling during the process.

- Wire Rope Fatigue: Abnormal phenomena such as broken wires, broken strands, corrosion, deformation, and wear appear on the surface of the wire rope. During normal use, the wire rope is subjected to external forces such as friction, impact, and compression, resulting in wear and tear of the wire rope.

- Kinking: The permanent deformation of the wire rope caused by local twisting is called kinking. If the end of the wire rope strand is not tied when tension is applied, the strand will rotate in the opposite direction, which is the inherent factor causing kinking of the wire rope.

Wire Rope Troubleshooting

- When installing or replacing wire ropes, attention should be paid to selecting ropes with good anti-kinking performance and matching the rope twist direction with the winch drum. Use the correct rope threading technique to avoid generating twisting stress during the threading process. In the event of wire rope twisting during operation, the lifting task should be temporarily suspended, and with proper safety precautions, release the internal stress of the wire rope by removing the wedge-shaped end, then reinstall and secure the wedge-shaped head. Before resuming operation, perform a lifting test to confirm that the problem of wire rope twisting is resolved.

- The rope guide is a vulnerable component, and when it is severely worn, it will fail to guide the rope properly, resulting in rope entanglement, it should replace the rope guide at this time. In tilted lifting operations, the rope guide is most prone to wear, so in production, the lifted load should be kept perpendicular to the electric hoist.

- During the daily operation of the crane, strengthen the monitoring of the wire rope’s condition and judge its usage status. Once it reaches the relevant scrapping criteria, immediately replace the wire rope that meets the scrapping criteria.

- Solving wire rope faults may require components such as wire rope and rope guides.

3. Controller Faults

Common faults of the controller include poor contact and contact not closing. The causes of these problems are severe oxidation of the contact contact surface, uneven contact surface, loose or worn controller mechanism. Damaged remote controllers are also common failures.

Troubleshooting the controller should always check the contact condition, tighten the loose fixing bolts, replace the damaged parts in time, and add lubrication to the rotating parts.

4. Brake Faults

- Brake Failure: Brake failure is indicated by excessive sliding distance during braking, typically exceeding 80 mm.

- Inability to Release the Brake: The main reasons include the hinge point being jammed and difficult to rotate normally, the presence of air or lack of oil in the hydraulic solenoid and hydraulic push rod cylinder, excessively elastic main spring, dirt on the brake pad, and high voltage leading to the burnout of rectifying coils and components, as well as faults in the electromechanical device circuit.

- Continuous Decrease in Brake Torque: This is mainly caused by brake pad wear, severe wear of the hinge point hole in the brake frame, and continuous relaxation of the main spring.

- Brake Heating: Auxiliary spring damage or bending in short-stroke brakes, and rough working surface of the brake wheel. Improper clearance between the brake pad and the brake wheel.

Specific Brake Maintenance Measures

- Brake failure may be due to excessive clearance in the brake, the presence of oil contamination on the friction surface, or excessive wear of the friction surface. The appropriate clearance can be achieved by slightly tightening the nut. If the pressure spring is fatigued, it should be replaced. If the brake ring is severely worn and cannot ensure a reasonable braking clearance, the brake ring must be replaced. When replacing the brake ring, remove the brake wheel first, remove the original brake ring, slightly lubricate the new brake ring rubber ring with water, and embed it smoothly.

- Eliminate jamming and lubricate; evacuate air and add oil; adjust the main spring force; regularly clean the brake wheel inside the bridge crane, preferably using kerosene for cleaning, and lubricate the brake pad inside; replace burnt-out electromagnetic coils and components; check the electrical circuit.

- Timely replace brake pads with wear exceeding 50% of the original thickness and replace pins with wear exceeding 5%, using methods such as reaming and installing new pins to eliminate wear in the holes.

- Replace or repair auxiliary springs; machine the working surface of the brake wheel as required; adjust the clearance.

- Solving brake failures may require components such as pressure springs, main springs, auxiliary springs, small shafts, central shafts, brake rings, friction pads, and other parts.

5. Reducer Faults

- Oil leakage: Oil leakage occurs when the surface of the reducer is not smooth, and the lubricant loses its effectiveness. Uneven sealing coating or damaged sealing gasket on the sealing surface, as well as deformation of the casing or loosening of connecting bolts, can also cause oil leakage.

- Gear malfunction: During operation, gears may experience fracture and wear. Corrosion may also occur during operation.

- Shaft fracture: Shaft fracture occurs when the reducer shaft is subjected to bending forces and breaks.

Maintenance Measures for Reducer Equipment

- Adjust the flatness of reducer components to meet requirements; replace seals; repair the casing, and replace it if deformation is severe; tighten bolts.

- Replace bearings.

- Replace gears.

- Solving reducer failures may require the use of components such as gears, bearings, sealing gaskets, and sealing boxes.

6. Electrical System Faults

- Motor failure: Motor starting torque is small, can not start, abnormal sound.

- Isolated conductor rail failure: The main power supply system failure is mainly power supply isolated conductor rail failure. Such as power failures caused by isolated conductor rail, the obvious deformation of the conduit caused by the collector can not be moved, brush side abrasion and the surface of the granular pits, the wobble of the conduit is too large during work, brush wear too fast, device sliding with a large sound and shell abrasions. The reason is often the deformation caused by the inappropriate installation of the guide rail, the ambient temperature is too high thermal expansion caused by the jamming, the collector of the incorrect installation and positioning deviations, etc.

- AC contactor failure: Overhead crane in operation due to the contactor points and closes the action frequently, so it is easy to contactor coil burning and broken wire failure, due to the coil fixing bolt loosening, contactor rotating mechanism shifting leads to the movable and static iron core suction misalignment, the core suction holding current increases; make auxiliary contact poor contact, coil voltage at both ends of the coil is reduced. Caused the coil failure; contactor dynamic and static contacts are burned or and burned by the arc.

- Resistor main faults: Resistive broken wire, will lead to rotor open circuit; resistive grounded, resulting in rotor current imbalance, serious rotor winding serious heat; resistive connecting terminals heat.

Maintenance Measures of Electrical System

- Check whether the three-phase power supply of the motor is normal with an electrician’s meter, whether there is undervoltage, phase shortage, etc., whether the motor collector ring, carbon brush and wire are normal, whether the insulation resistance of the motor is qualified or not, and the motor shaft or bearing is worn out or damaged will also cause this fault. Check to determine the cause of the corresponding maintenance or replacement of damaged components.

- Strengthen the inspection of vulnerable parts of the power supply sliding isolated conductor rail system, timely repair or regular replacement of the collector. Periodically or frequently check the condition of the isolated conductor rail guide and adjust the sliding hanger to allow the conduit to extend freely. Increase the thermal expansion section of the conduit, add shades and use heat shields at outdoors.

- Regularly carry out comprehensive inspection and maintenance of the electrical components in the power cabinet. Check the coil wiring and the fixed bolts for looseness, and eliminate the defects immediately; tighten the loose contacts and replace the damaged contacts in time. And do a good job of contactor contact closure during the same period of inspection, adjustment work.

- Regularly check the resistor for hot spots and broken wires, tighten the connecting bolts, and regularly check the insulation resistance of the rotor and resistor and whether the three-phase rotor current is balanced.

- Troubleshooting the electrical system may use components such as collectors, cables, bearings, and contactors.

After a long time of use, some parts of the bridge crane will inevitably be subject to wear and tear, wear and tear to reach the end-of-life standards need to be replaced with new parts to avoid accidents. Common failures of overhead cranes include component faults, controller faults, brake faults, reducer faults, electrical faults and so on. The parts that may be used to solve these faults are:

- Component fault: wire ropes, rope guides, hooks, pulleys, wheels, reels

- Controller fault: remote control

- Brake fault: pressure spring, main spring, auxiliary spring, small shaft, mandrel, brake ring, brake wheel, friction pads, brake linings

- Reducer fault: gears, bearings, sealing gaskets, sealing box, reducer

- Electrical fault: motor rotor, bearing, electromagnetic coil, slip ring, carbon brush, collector